Welcome to nima!

Inspiring. Influencing. Connecting. Supporting. Transforming.

Nima (formerly the UK BIM Alliance) is a not-for-profit, volunteer-led virtual organisation. It promotes information management best practices, helping to support digital transformation across the built and managed environment.

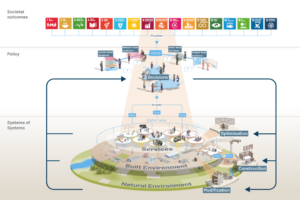

Our ultimate vision is a thriving and sustainable built and natural environment transformed by exploiting purpose-driven data. As trusted advisors, we facilitate the implementation and integration of practical information management practices across our built and environmental infrastructure.

Our mission is to inspire, influence, connect and support everyone active in a transformed built and managed environment, and to enable everyone to better manage information vital to the needs of our times.

With trusted data, great things happen.

nima news alerts

Stephen Holmes receives nima honour

Stephen Holmes, a volunteer who has contributed extensively to nima since it was originally founded as the UK BIM Alliance in 2016, was announced as the inaugural winner of the nima Outstanding Contribution Award. The…

nima podcast previews two Virtual Spring Conference 2024 keynotes

The nima podcast – That Information Management Podcast – has recorded interviews with two of the keynote speakers at this week’s Virtual Spring Conference 2024. The first podcast features Rene Morkos, CEO of US-based ALICE…

What is a digital twin?

A new international standard is set to create greater consistency of understanding around digital twins. The term ‘digital twin’ has been widely used (and misused) in recent years. The phrase was first applied in the…

Opportunity to participate in the Information Management “Mandate” Review

(via Construction Leadership Council) A review of the Information Management “Mandate” has now commenced through the mobilisation of a Task Group to integrate the success of the BIM Mandate with the current IM Mandate. The…

Good information management is critical to running HMP Five Wells

HMP Five Wells is the UK’s largest Category C resettlement prison, located in Wellingborough, Northamptonshire. Built almost entirely from standardised components, with a unique design that enables more contact…

Sign up for the latest news

Did you know the buildingSMART UK and Ireland chapter has been powered by nima (formerly the UK BIM Alliance) since 2017? bSUKI is the UK and Ireland Chapter of buildingSMART International.

The project activities of nima and bSUKI are now more visible, integrated and accessible to you. We are responsible for gathering industry requirements and representing the UK and Ireland’s needs at international level. When standards are being developed, we help to ensure these needs are catered for.